Interview by BizJournal: Columbus edition

On July 31st, 2015, the Columbus BizJournal posted an interview with Avcom.

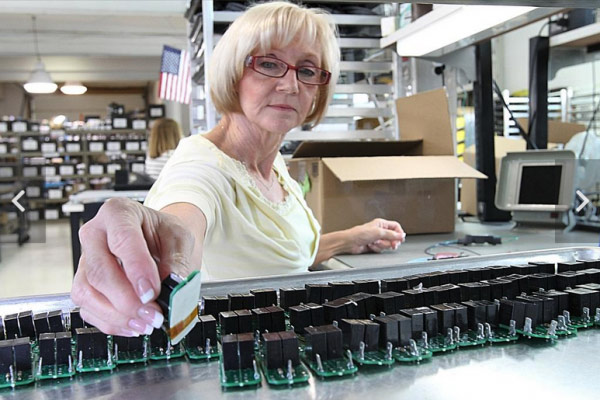

Q&A with Barbara Wiese, co-owner, Avcom SMT

by Melissa Kossler Dutton

MADE IN CENTRAL OHIO

Avcom: Circuit board assembler serves diverse clients

Business: Electronics manufacturing service that assembles electronic parts for circuit boards.

One product everyone would recognize: Circuit board with electronics parts installed, soldered, inspected and cleaned.

Based: Westerville, near Columbus, OHIO

Founded: 1970

Employees: 15

Owners: Paul Wiese, electronics engineer and president, and wife Barbara

2014 revenue range: $1.5 million to $2.5 million

We hear finding talent to pursue jobs in manufacturing is difficult because of a perception among job candidates about the desirability of the work. How can that be combated? We have welcomed classes of students to show them the manufacturing process. We deal with an Ohio State University professor who recently brought a class of potential engineering students from area middle schools to show them the machinery and how small the electronic parts are. They were very interested and listened to our production manager detail how our process works.

Teachers should take students to tour any facility that will allow it. They need to actually see how things work. It also would be helpful if engineering students received applied training while in college. Most only receive technical training, which means they have to learn things like handling a soldering iron or understanding manufacturing processes on their own.

How did you stay in business as so much electronics manufacturing was shipped overseas? Do you see that changing?

Avcom kept in business by seeking the business that stayed in the United States, which for the most part is prototype work. We do a lot of jobs where the customer needs to make small quantities to test out the product. They realize that it’s not economical to send small jobs —those in the thousands range — overseas. Of course, tens of thousands and larger orders are more cost-effective to send overseas. Many foreign companies also don’t face the regulations and labor costs that we do. However, recently several companies are actively trying to bring production back to the United States because they see value in using American labor.